NOW TAKING ORDERS ONLINE

Services

Ellapack offer a one stop facility for all your blow moulding needs, from concept design through to full production. With many years of experience in blow moulding we have help many of our customers enhance their manufacturing by maintaning a high level of quality and service. Our expertise in tooling design & development and being proactive with repair and refurbishment of your tooling ensures your products are always on time and first class.

Tool Design & Development

Ellapack offer tool Design & Development service to help customers bring their product to life.

Product Design

Ellapack, in conjunction with our toolmaker & design partners, can produce product designs from customer design briefs. The process is stepped out in stages. Each step is conducted after customer approval of each preceding step.

Produce a product concept drawing

After discussions with the customer as to the proposed new product, a CAD drawing will be produced.

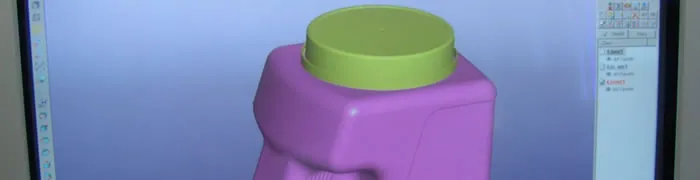

3-Dimensional Drawing

A 3-dimensional drawing of the proposed design can be viewed at your premises utilizing a computer on site, with the ability to also view any cross section in a selected colour.

Product Model

A product model of the design can be produced by either a solid wooden model or a laser built-up model as a hollow article.

Tooling

The tooling style can be produced in a variety of styles depending on the design features and annual requirements. Product life cycle is also taken into consideration.

First-Off Tool Samples

The first-off tool samples are produced to confirm design & specification characteristics, also to trial on filling &/or assembly lines for verification.

Manufacture the product

After all the above steps have been approved the product will be manufactured to the customer’s requirements.

Warehousing & Logistics

Having recently completed construction of its new warehouse, Ellapack have the space to store stock to ensure you never run out.

Quick Contact

COPYRIGHT | Ellapack Pty Ltd